PET Bottle Carbonated Drink Filling Line

Cola, Sprite, Soda, speaking water, cocktail, flavored water…the variety of carbonated beverage is ever changing. New trend, new products and new packaging are emerging continuously.

For carbonated filling machines, how to rise up the filling temperature to reduce energy consumption? How to reduce foaming? How to keep accurate filling? How to avoid the residuals in the neck? How to preserve the CO2…it is not an easy task to handle all these challenges. However, no matter what products, Wanjin Machine will achieve your target with the best technology.

Meanwhile, Wanjin Machine filling machine can realize multiple functions in one equipment. One machine can do water, carbonated drinks and hot filling products.

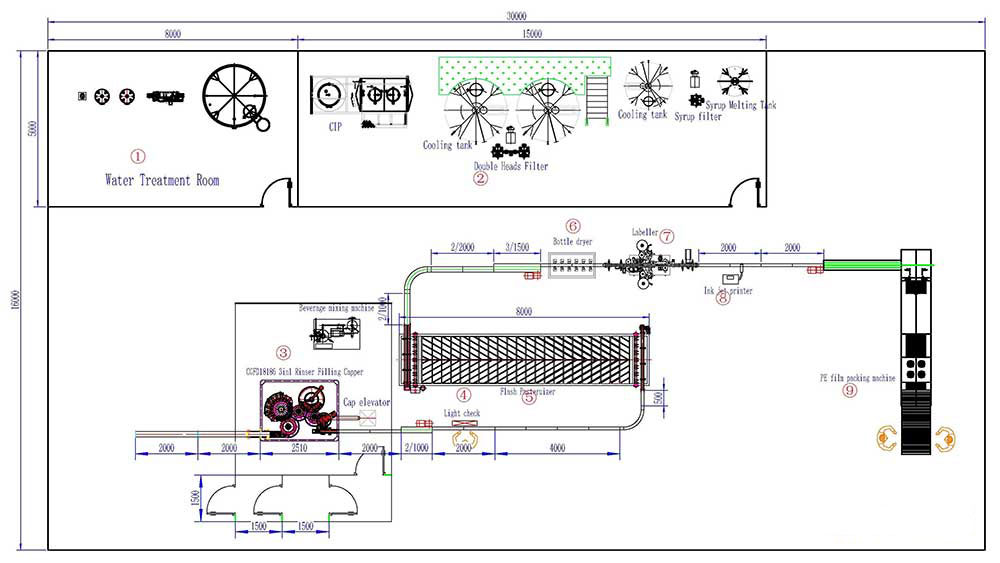

FACTORY DESIGN