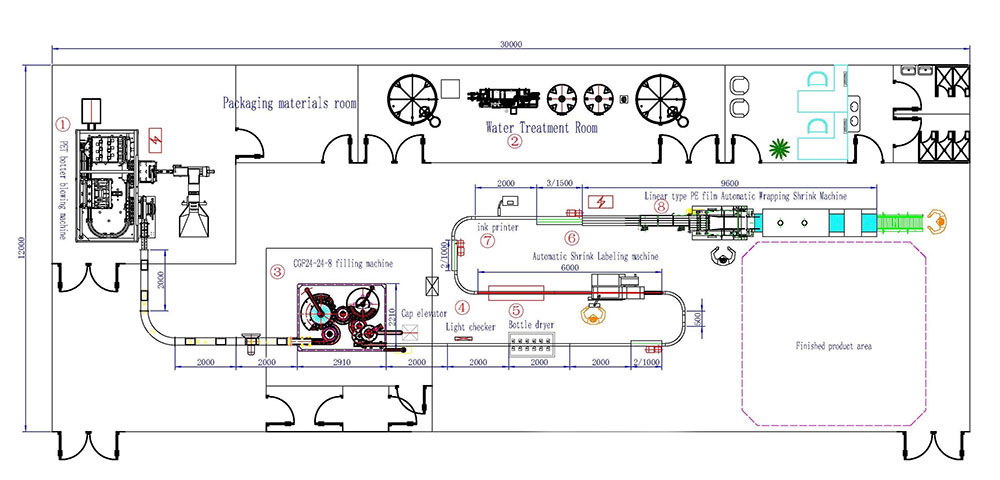

3-10L FILLING LINE SOLUTION

– This 3L-10L water bottle filling machine is mainly used for washing, filling and capping PET bottle which can fill non- carbonated drinks such as mineral water, pure water, wine and so on.

– Bottle washing, filling and capping are achieved in one machine.

– The contact time is shorten between material and the outside. And improved the health conditions, production capacity and economic benefits.

– CGF series bottling machine adopts hanging type conveying-bottle structure to make changing bottle mold more convenient, faster and more laborsaving.

– The main machine adopts advanced PLC control technology. The key electric elements adopt Mitsubishi, Omron, Siemens, etc international famous products..

3-10L FILLING LINE SOLUTION